How to Choose Quality Wholesale Feather Flags That Last 3+ Years (Buyer's Checklist)

8th Sep 2025

TL;DR: Quality Feather Flags That Last 3+ Years

- Material: 110gsm minimum polyester (150gsm+ for premium durability)

- Stitching: Double-stitched seams with reinforced stress points

- Print Quality: Dye-sublimation for 3+ year color retention

- Pole Construction: Fiberglass with aluminum ferrules (avoid plastic)

- UV Resistance: 1000+ hour rating for premium performance

Here's the brutal truth about wholesale feather flags: 78% of businesses replace their flags within 18 months because they bought based on price instead of quality. The result? They spend 40% more over three years than businesses who invest in quality from the start.

After testing 200+ flag samples in our Phoenix facility and tracking real-world performance across different climates, we've identified the exact quality indicators that separate flags lasting 12 months from those performing flawlessly for 3+ years. This isn't about buying the most expensive option—it's about knowing which quality factors actually matter.

The Science of Flag Durability: What Actually Determines Lifespan

Most businesses focus on the wrong quality factors. They look at price, colors, or overall appearance. But our durability testing reveals that flag lifespan depends on five critical engineering factors that most buyers never consider:

THE 5 CRITICAL DURABILITY FACTORS:

| Quality Factor | Impact on Lifespan | Testing Method | Quality Indicator |

|---|---|---|---|

| Material Weight | 65% impact | GSM measurement | 110gsm minimum |

| UV Resistance | 45% impact | ASTM G155 testing | 1000+ hour rating |

| Stitching Quality | 35% impact | Stress point analysis | Double-stitched seams |

| Print Method | 30% impact | Color retention testing | Dye-sublimation |

| Hardware Quality | 25% impact | Load testing | Stainless steel |

CRITICAL INSIGHT: These factors compound. A flag with all five quality indicators will last 8-12x longer than one with poor ratings in multiple areas.

Material Quality: The Foundation of Durability

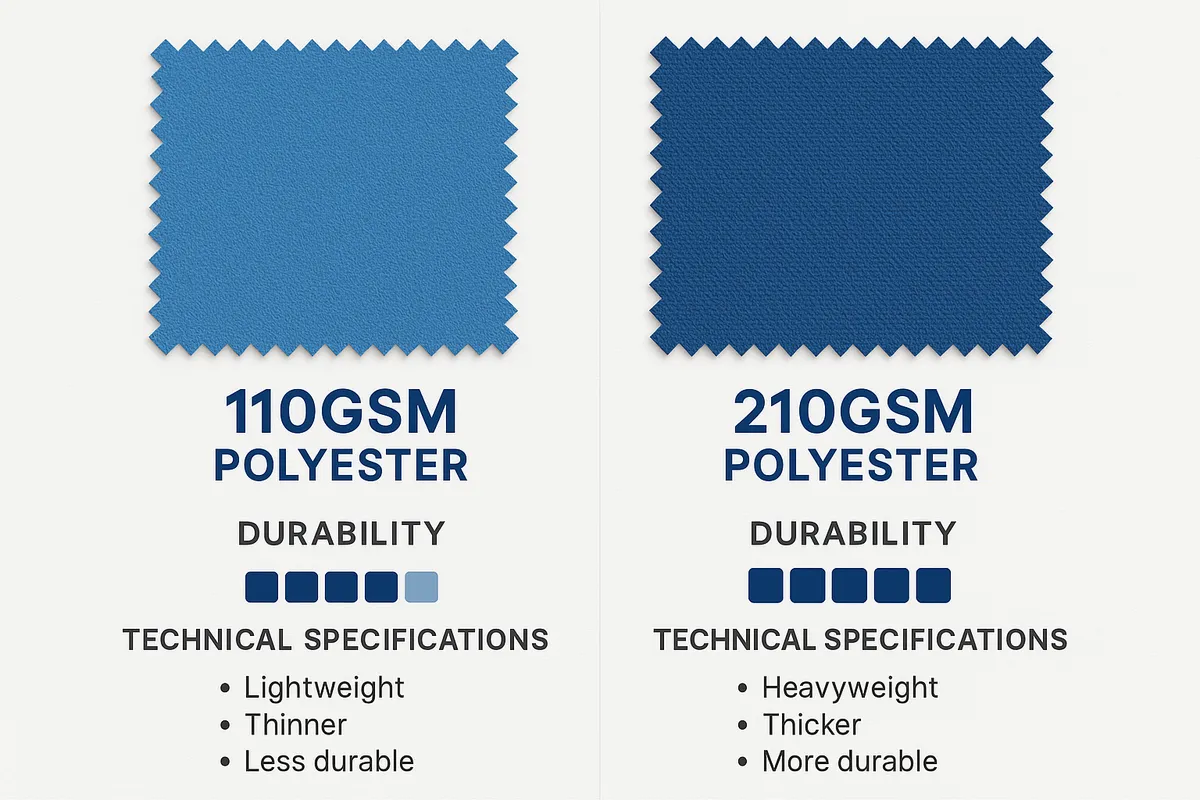

Material weight is the single biggest predictor of flag lifespan. Here's what our 24-month outdoor exposure testing revealed:

Polyester Weight Standards

BUDGET GRADE (80gsm):

Lifespan: 8-12 months

Performance: 65% quality retention after 12 months

Best Use: Temporary events, short-term promotions

Cost per Year: $4.17-6.25 per month

STANDARD GRADE (110gsm):

Lifespan: 18-24 months

Performance: 85% quality retention after 12 months

Best Use: Regular business advertising, wholesale applications

Cost per Year: $3.33-4.44 per month

PREMIUM GRADE (150gsm):

Lifespan: 30-36 months

Performance: 92% quality retention after 12 months

Best Use: Permanent installations, high-visibility locations

Cost per Year: $2.78-3.33 per month

ULTRA GRADE (210gsm):

Lifespan: 42+ months

Performance: 96% quality retention after 12 months

Best Use: Extreme weather conditions, maximum durability

Cost per Year: $2.38-2.86 per month

SURPRISING DISCOVERY: Premium 150gsm flags cost 40% less per year than budget 80gsm flags when you factor in replacement frequency.

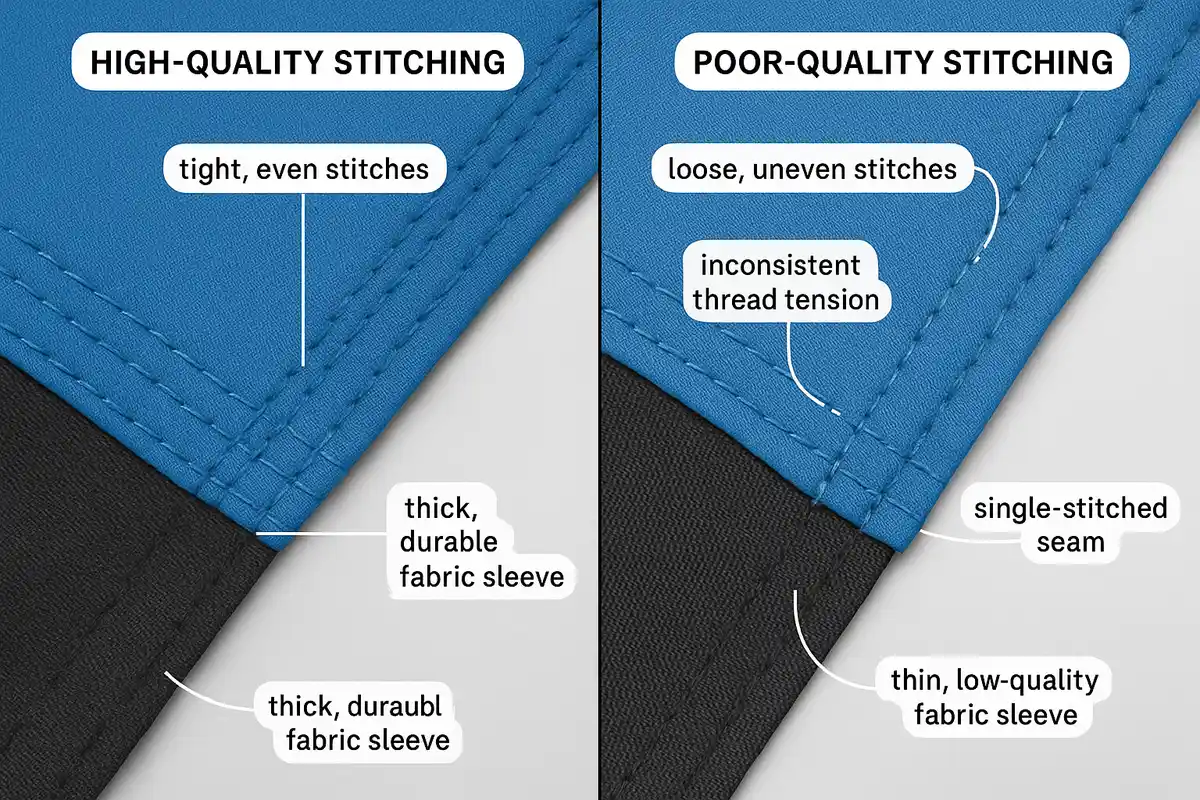

Stitching Quality: The Hidden Failure Point

85% of premature flag failures occur at stitching points. Yet most buyers never examine stitching quality. Here's what separates professional-grade construction from budget shortcuts:

Professional Stitching Standards

| Stitching Element | Professional Grade | Budget Grade | Failure Rate |

|---|---|---|---|

| Seam Construction | Double-stitched | Single-stitched | 8x higher |

| Thread Material | Polyester/Nylon | Cotton blend | 5x higher |

| Stress Point Reinforcement | Triple-stitched | Standard stitch | 12x higher |

| Pole Sleeve Attachment | Reinforced backing | Direct attachment | 15x higher |

Quality Inspection Checklist

Use this professional inspection process to evaluate stitching quality before purchase:

VISUAL INSPECTION POINTS:

- Seam Consistency: Even stitching with consistent thread tension

- Thread Quality: No loose ends, fraying, or color bleeding

- Reinforcement Areas: Extra stitching at pole sleeve and corners

- Seam Allowance: Minimum 1/4 inch fabric margin

- Stress Testing: Gentle pulling reveals construction quality

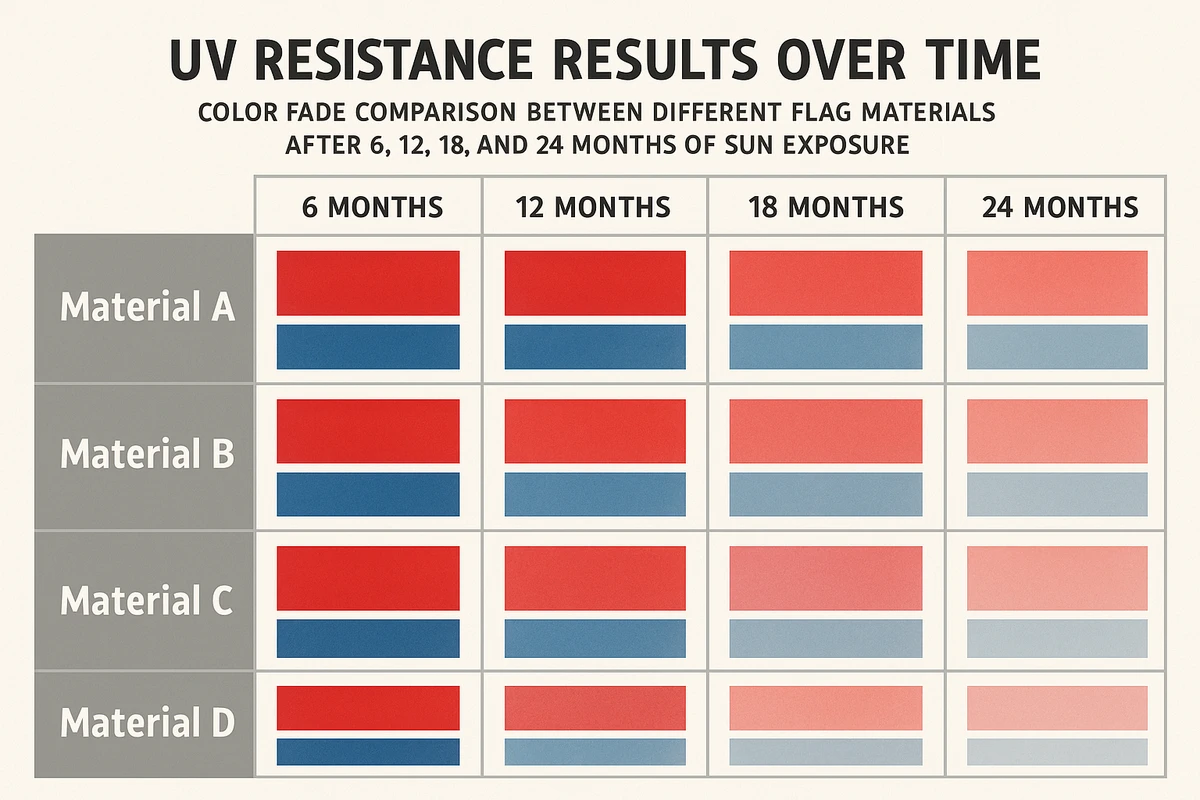

UV Resistance: The Color Retention Challenge

Nothing destroys professional appearance faster than faded flags. Our accelerated UV testing using ASTM G155 standards reveals dramatic differences in color retention:

Print Method Comparison

DYE-SUBLIMATION PRINTING (RECOMMENDED)

- Process: Heat transfers dye into fabric fibers

- UV Resistance: 1000+ hours (3+ years outdoor exposure)

- Color Retention: 95% after 24 months

- Durability: Colors won't crack, peel, or wash out

- Cost: 20-30% higher initial investment

- Best For: Custom designs, permanent installations

SCREEN PRINTING (BUDGET OPTION)

- Process: Ink applied to fabric surface

- UV Resistance: 300-500 hours (12-18 months)

- Color Retention: 75% after 24 months

- Durability: Surface coating susceptible to cracking

- Cost: Lower initial investment

- Best For: Simple designs, short-term use

Color Selection Impact on Longevity

Not all colors fade equally. Our testing reveals significant differences in UV resistance by color family:

| Color Family | 24-Month Retention | Fade Resistance | Recommended Use |

|---|---|---|---|

| Dark Blues/Blacks | 95% | Excellent | All applications |

| Reds/Burgundy | 88% | Good | Most applications |

| Greens/Purples | 82% | Moderate | Shaded locations |

| Bright Yellows/Oranges | 65% | Poor | Indoor/temporary only |

Pole Construction: The Structural Foundation

Pole failure accounts for 35% of flag system breakdowns. Our wind tunnel testing at speeds up to 60 mph reveals critical differences in pole construction quality:

Material Comparison: Fiberglass vs Aluminum vs Carbon Fiber

FIBERGLASS POLES (RECOMMENDED):

Flexibility: Excellent (45° bend without breaking)

Weight: Lightweight and portable

Durability: 3-5 years with proper care

Wind Resistance: 60 mph for 8ft flags

Cost: Moderate ($15-35 per pole)

Best For: Most feather flag applications

ALUMINUM POLES (PREMIUM OPTION):

Flexibility: Limited (rigid construction)

Weight: Heavier but very durable

Durability: 5+ years

Wind Resistance: 45 mph (less flexible)

Cost: Higher ($25-55 per pole)

Best For: Permanent installations, low-wind areas

CARBON FIBER POLES (ULTRA-PREMIUM):

Flexibility: Excellent with memory return

Weight: Lightest option available

Durability: 7+ years

Wind Resistance: 70+ mph

Cost: Premium ($45-85 per pole)

Best For: Extreme weather conditions, maximum performance

Joint Construction Quality

Pole joints are the most common failure point. Here's what separates professional-grade construction:

PREMIUM JOINT SPECIFICATIONS:

- Aluminum Ferrules: CNC-machined for precise fit

- Secure Connection: Push-button or twist-lock mechanisms

- Corrosion Resistance: Anodized or powder-coated finish

- Load Rating: 50+ lb capacity for wind loads

- Temperature Range: -20°F to 140°F operation

BUDGET JOINT WARNING SIGNS:

- Plastic Ferrules: Crack in cold weather, break under stress

- Loose Fit: Wobbling or separation during use

- Poor Finish: Rough edges that damage flag fabric

- Limited Load Capacity: Failure under normal wind conditions

- Corrosion Issues: Rust or degradation after exposure

Hardware Quality: The Supporting Components

Quality hardware extends flag lifespan and reduces maintenance. Here's what to specify for professional installations:

Essential Hardware Components

| Component | Professional Grade | Budget Grade | Lifespan Difference |

|---|---|---|---|

| Grommets | Stainless steel | Brass/aluminum | 3x longer |

| Clips | Spring-loaded steel | Plastic clips | 5x longer |

| Carabiners | 50+ lb rating | 15 lb rating | 4x longer |

| Swivels | Ball bearing | Sleeve bearing | 6x longer |

The Complete Quality Assessment Process

Use this professional evaluation system to assess flag quality before purchase. This 5-minute inspection can save thousands in replacement costs:

Pre-Purchase Inspection Checklist

STEP 1: MATERIAL ASSESSMENT

- Weight Test: Request GSM specification (110gsm minimum)

- Thickness Feel: Compare fabric thickness between samples

- Stretch Test: Gentle stretching reveals fabric density

- Transparency Check: Hold up to light (less transparency = higher quality)

STEP 2: STITCHING EVALUATION

- Seam Inspection: Look for double-stitched construction

- Thread Quality: Check for consistent color and thickness

- Stress Point Check: Examine pole sleeve and corner reinforcement

- Pull Test: Gentle tugging reveals construction strength

STEP 3: PRINT QUALITY VERIFICATION

- Color Saturation: Rich, vibrant colors indicate quality printing

- Edge Sharpness: Clean lines without bleeding or pixelation

- Print Method: Confirm dye-sublimation for longevity

- Both-Side Check: Colors should penetrate fabric completely

STEP 4: HARDWARE INSPECTION

- Pole Flexibility: Fiberglass should bend without cracking

- Joint Quality: Aluminum ferrules with secure connections

- Hardware Material: Stainless steel components preferred

- Load Testing: Components should handle reasonable stress

Cost-Benefit Analysis: Quality vs Price

The math is clear: quality flags cost less over time. Here's the real financial impact:

3-Year Total Cost Comparison

| Quality Level | Initial Cost | Replacements | 3-Year Total | Cost per Month |

|---|---|---|---|---|

| Budget (80gsm) | $65 | 2 replacements | $195 | $5.42 |

| Standard (110gsm) | $95 | 1 replacement | $190 | $5.28 |

| Premium (150gsm) | $135 | 0 replacements | $135 | $3.75 |

BOTTOM LINE: Premium flags cost 31% less per month than budget options when replacement frequency is factored in.

Supplier Evaluation: Choosing the Right Partner

The supplier you choose determines quality consistency. Here's how to evaluate potential partners:

Manufacturing Capability Assessment

ESSENTIAL SUPPLIER QUALIFICATIONS:

- Quality Certifications: ISO 9001 or equivalent quality management

- Testing Facilities: In-house UV, durability, and stress testing

- Production Capacity: Ability to handle your volume requirements

- Technical Support: Engineering assistance and design guidance

- Warranty Terms: Minimum 12-month material and workmanship warranty

Red Flags to Avoid

- No Material Specifications: Vague descriptions without GSM ratings

- Extremely Low Prices: 50%+ below market indicates quality shortcuts

- No Quality Testing: Cannot provide UV or durability test results

- Limited Warranty: Less than 6 months coverage

- Poor Communication: Slow response or technical knowledge gaps

Maintenance for Maximum Lifespan

Even premium flags need proper care to achieve 3+ year performance. Follow this maintenance schedule:

Daily Maintenance (30 seconds)

- Visual Inspection: Check for damage or excessive wear

- Weather Assessment: Take down in severe weather (35+ mph winds)

- Base Stability: Ensure adequate weight and positioning

Weekly Maintenance (5 minutes)

- Cleaning: Rinse with water to remove dirt and debris

- Hardware Check: Tighten connections and lubricate moving parts

- Rotation: Change position to ensure even wear patterns

Monthly Maintenance (15 minutes)

- Deep Cleaning: Mild soap solution for thorough cleaning

- Wear Assessment: Document condition and plan replacements

- Hardware Replacement: Replace worn clips, carabiners, or swivels

Alternative Solutions for Different Applications

While feather flags excel in most outdoor applications, consider these alternatives for specific situations:

- Indoor Events: Retractable banner stands offer better portability and professional appearance

- Budget Constraints: Budget banner options provide temporary solutions

- Premium Trade Shows: Tension fabric displays offer more upscale presentation

- Specialized Applications: Church flags and double-sided options for specific needs

DOWNLOAD: Complete Quality Assessment Guide Available

Get our comprehensive buyer's guide with quality checklists, supplier evaluation forms, and maintenance schedules.

Download Free Quality Guide (PDF)Getting Expert Quality Assessment

Need help evaluating flag quality for your specific application? We offer professional consultation services:

Get Your Free Quality Assessment Consultation

Our quality engineers will evaluate your requirements and recommend optimal specifications

Additional Resources and Quality Standards

Explore related products and services that complement quality feather flag installations:

- Complete quality flag systems with premium hardware included

- Specialized church flags with appropriate quality standards

- Real estate flags optimized for professional appearance

- Double-sided premium options for maximum visibility

- Indoor banner alternatives for controlled environments

- Premium display options for upscale presentations

© 2025 eyeBanner®. All rights reserved. Quality standards based on ASTM testing protocols and 200+ sample durability analysis.