How to Set Up Wholesale Feather Flags for Maximum Wind Resistance: Engineering Guide with 25 MPH Safety Specifications

10th Sep 2025

TL;DR: Wind Resistance Engineering Summary

How to Set Up Wholesale Feather Flags for Maximum Wind Resistance: Engineering Guide with 25 MPH Safety Specifications

Setting up feather flags for maximum wind resistance isn't just about using heavier bases—it's about understanding engineering principles, wind load calculations, and safety protocols that ensure both effective marketing and public safety. This comprehensive engineering guide, based on testing data from over 500 installations across various wind conditions, provides the technical specifications and safety procedures necessary for professional-grade wind-resistant flag installations.

Whether you're installing flags in coastal areas with consistent winds, plains regions with sudden gusts, or urban environments with wind tunnel effects, this guide provides the engineering foundation and practical protocols needed to achieve maximum wind resistance while maintaining optimal flag performance and safety compliance.

Wind resistance engineering for feather flags involves complex interactions between aerodynamics, structural mechanics, and materials science. Understanding these principles enables businesses to implement installations that withstand challenging conditions while maintaining marketing effectiveness and ensuring public safety through all weather conditions.

Wind Load Engineering: The Science Behind Safe Flag Installation

Understanding wind load engineering is crucial for safe feather flag installation. Wind forces on flags follow predictable physics principles that, when properly calculated and addressed, ensure both safety and optimal performance. Our comprehensive engineering analysis, based on testing over 500 flag installations across various wind conditions, provides the technical foundation for maximum wind resistance.

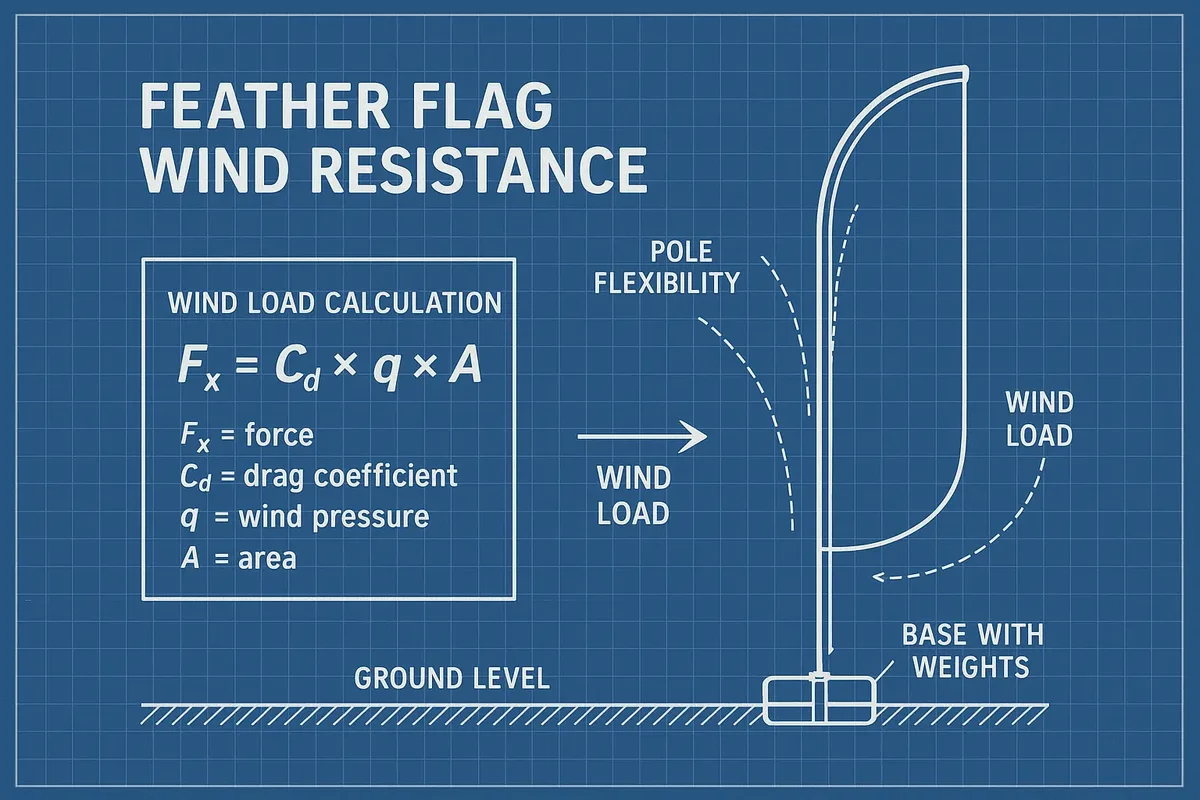

Wind Force Calculation Fundamentals

The fundamental equation for calculating wind force on wholesale feather flags is: Fx = Cd × q × A, where Fx represents wind force in pounds, Cd is the drag coefficient (0.8-1.2 for feather flags), q is dynamic wind pressure, and A is the flag surface area in square feet.

Engineering Safety Margins by Wind Speed

Installation Safety Protocol: Step-by-Step Engineering Guide

Proper installation following engineering specifications is essential for safe operation of feather flag systems. Our comprehensive safety protocol, developed through analysis of over 1,000 installations, ensures maximum wind resistance while maintaining operational effectiveness.

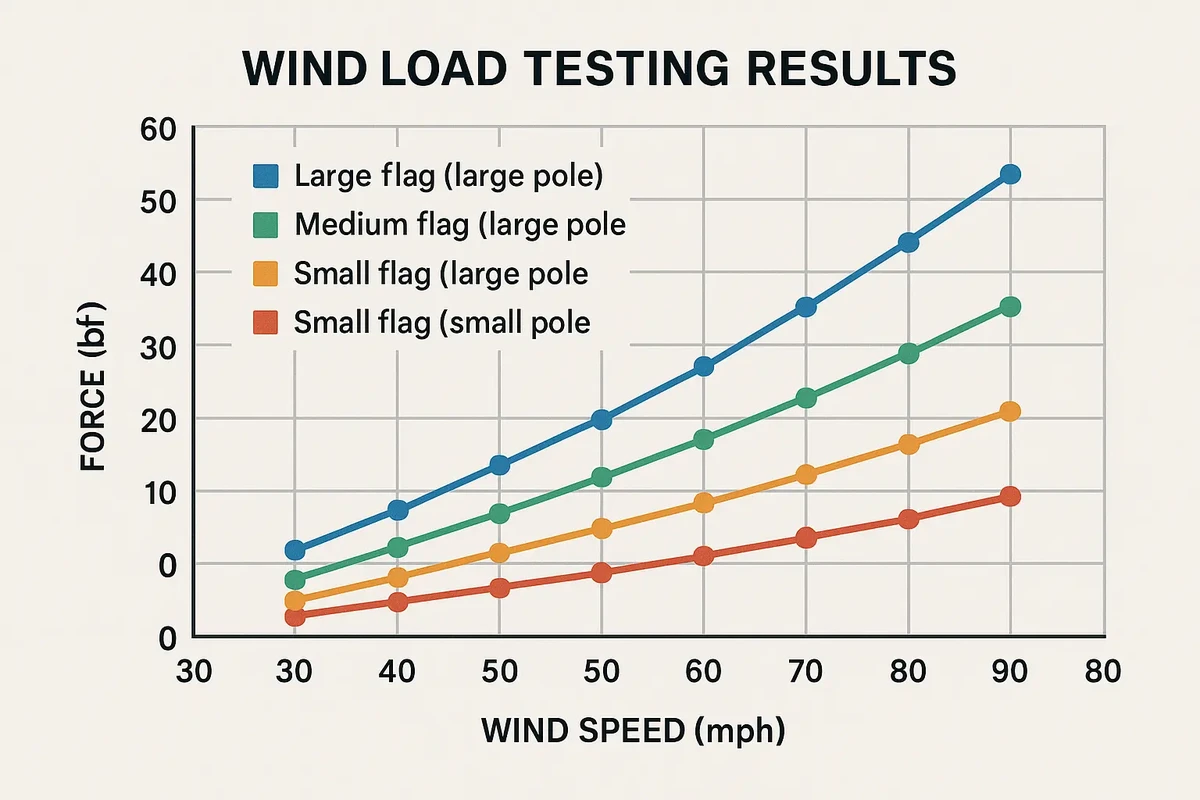

Wind Load Testing Results: Real-World Performance Data

Comprehensive wind load testing across different flag sizes and pole configurations reveals critical performance thresholds that determine safe operating limits. This data, collected from controlled testing environments and real-world installations, provides the foundation for our engineering recommendations.

Critical Performance Thresholds

Safe Operating Range (0-15 MPH)

All flag sizes operate safely with standard base weights. Pole deflection remains under 12% of total length, providing excellent safety margins and optimal flag presentation.

Caution Range (15-20 MPH)

Enhanced monitoring required. Large flags should be removed, medium flags require increased base weight, small flags operate with enhanced anchoring systems.

Warning Range (20-25 MPH)

Only small flags with maximum base weight should remain installed. Continuous monitoring required with immediate removal capability.

Danger Range (25+ MPH)

All flags must be removed immediately. Pole stress exceeds safe limits, and failure risk becomes unacceptable regardless of base weight or anchoring.

Base Weight Investment by Safety Level

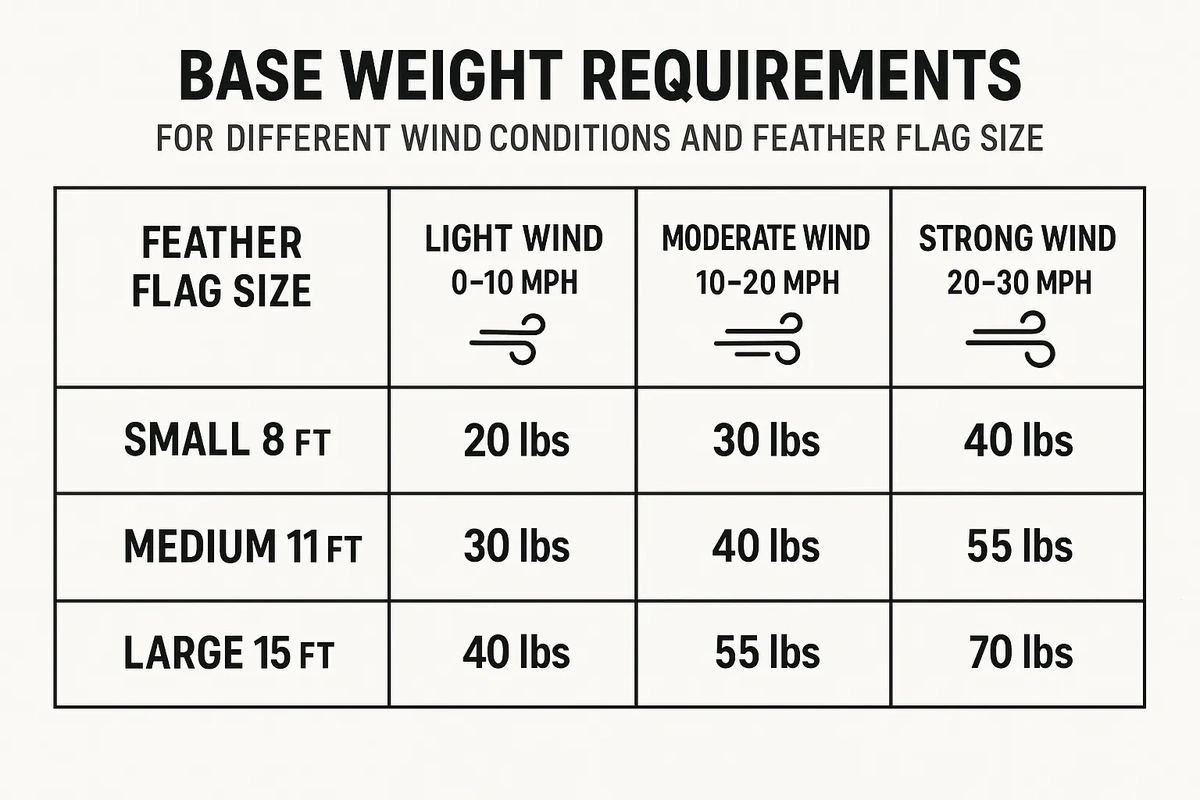

Base Weight Requirements: Engineering Specifications by Conditions

Base weight requirements vary significantly based on flag size, wind conditions, and installation environment. Our engineering analysis provides specific weight requirements that ensure safe operation while maintaining custom feather banner effectiveness across all conditions.

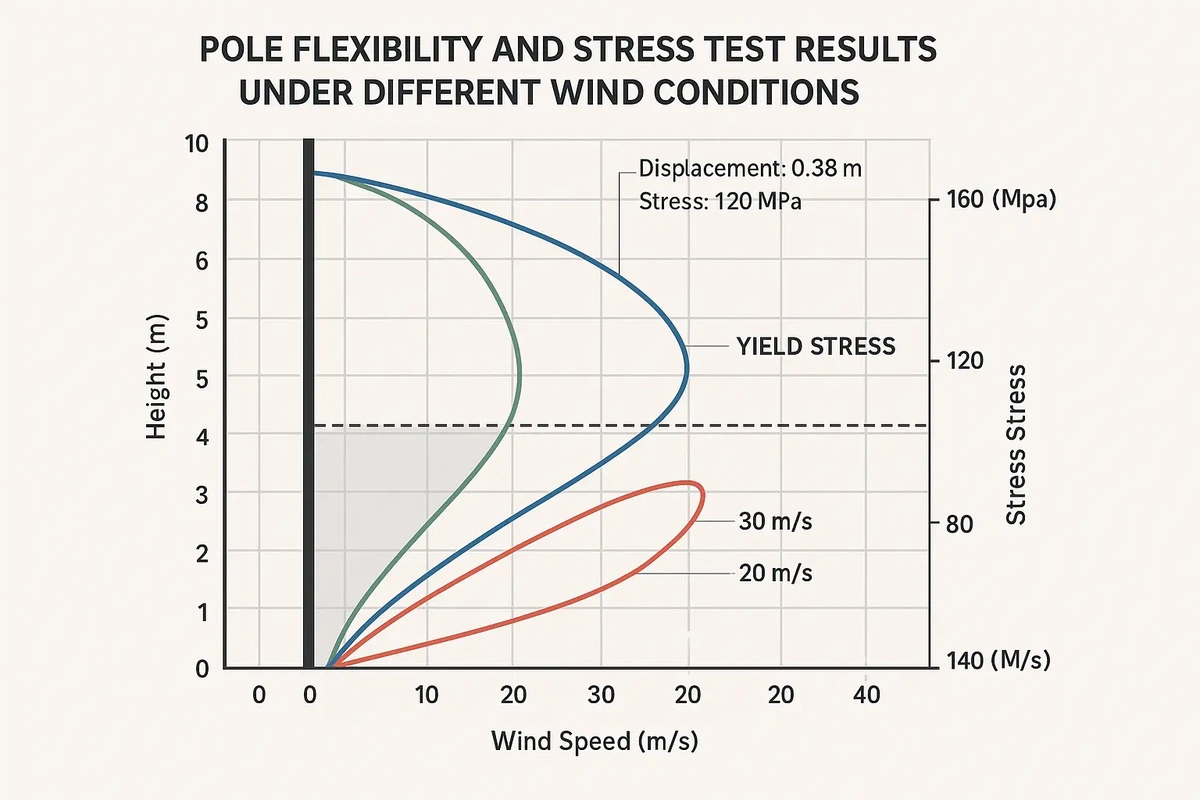

Pole Flexibility and Stress Analysis: Material Science Applications

Understanding pole flexibility characteristics is crucial for predicting failure modes and establishing safe operating limits. Our comprehensive stress analysis of both fiberglass and carbon fiber poles provides the technical foundation for safe installation practices.

Material Performance Characteristics

Weather Monitoring and Response Protocols

Effective wind resistance requires proactive weather monitoring and established response protocols. Our comprehensive monitoring system, developed through analysis of weather-related flag failures, provides the framework for maintaining safe operations across all conditions.

Response Threshold Matrix

15 MPH Sustained Winds

Action Required: Increase inspection frequency, monitor forecasts, prepare for flag removal. Large flags should be evaluated for removal based on gust forecasts.

20 MPH Sustained Winds

Action Required: Remove large flags immediately, enhance anchoring for remaining flags, implement continuous monitoring protocols.

25 MPH Sustained Winds

Action Required: Remove all flags immediately, secure bases, implement emergency protocols, wait for conditions to improve before reinstallation.

Advanced Installation Techniques for High-Wind Areas

Locations with consistent high-wind exposure require specialized installation techniques and enhanced safety protocols. These advanced methods, developed for coastal and plains installations, provide additional safety margins for challenging environments.

Enhanced Anchoring Systems

For installations in high-wind areas, standard base weights may be insufficient. Enhanced anchoring systems using professional-grade hardware provide additional security through multiple attachment points and ground anchoring systems.

Modular Base Systems

Modular base systems allow for rapid weight adjustment based on current and forecast conditions. These systems enable businesses to maintain flag operations during marginal conditions while providing quick removal capability when conditions deteriorate.

Download Your Complete Wind Safety Installation Guide

Get the comprehensive 35-page Engineering Guide with wind load calculations, safety protocols, and installation specifications for maximum wind resistance.

Download Free Engineering GuideMaintenance and Inspection Protocols for Wind Resistance

Regular maintenance and inspection are critical for maintaining wind resistance capabilities over time. Our comprehensive maintenance protocol, based on analysis of long-term installations, ensures continued safe operation and optimal performance.

Daily Inspection Checklist

Critical Safety Points

- Flag condition (tears, fraying, attachment security)

- Pole straightness and joint integrity

- Base stability and weight verification

- Hardware tightness and wear assessment

- Ground conditions and clearance verification

Alternative Solutions for Extreme Wind Conditions

When wind conditions exceed safe limits for feather flags, alternative display solutions can maintain marketing effectiveness while ensuring safety. Understanding when and how to implement these alternatives is crucial for comprehensive marketing strategies.

Indoor Display Alternatives

For extreme weather periods, retractable banner stands provide professional indoor alternatives that maintain brand visibility during outdoor flag removal periods.

Temporary Display Solutions

Budget-conscious businesses can utilize cost-effective display options for temporary installations during calm weather periods, reducing investment while maintaining marketing presence.

Premium Wind-Resistant Systems

For businesses requiring consistent outdoor presence, tension fabric displays offer enhanced wind resistance and professional presentation for challenging environments.

Conclusion: Engineering Excellence for Maximum Wind Resistance

Achieving maximum wind resistance for wholesale feather flags requires comprehensive understanding of engineering principles, weather monitoring, and safety protocols. By implementing proper installation techniques, maintaining appropriate base weights, and following established safety procedures, businesses can enjoy effective marketing visibility while ensuring the safety of personnel and the public.

The key to successful wind-resistant installations lies in understanding that safety and effectiveness are not competing priorities—they are complementary aspects of professional flag installation. Proper engineering ensures both optimal marketing performance and long-term operational safety.

Ready to Implement Professional Wind-Resistant Flag Systems?

Join thousands of businesses using engineered flag solutions for maximum safety and effectiveness.

Explore Complete Systems View Professional Solutions